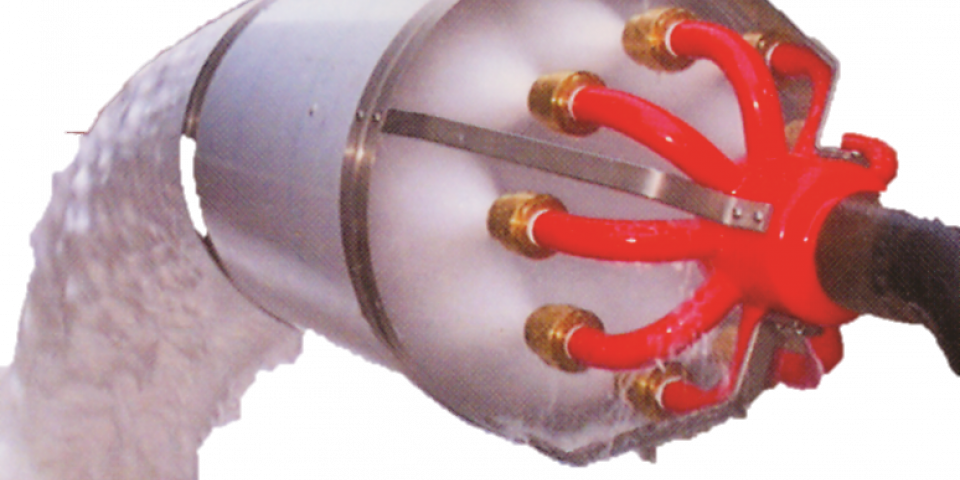

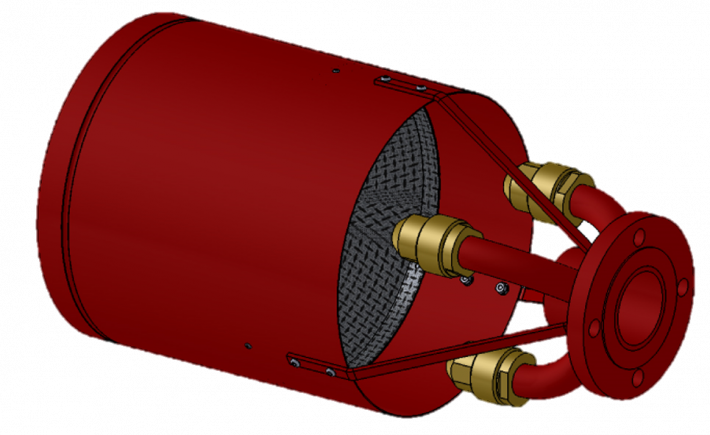

MX Bund Pourers

Key Features

- Manufactured in the UK

- ISO9001 Quality Controlled

- High Output Medium Expansion Foam Production

- Flow Engineered to suit Client

- 316 Stainless Steel Pourer Tube and Internals

- Flows from 600 litres/min to 1,800 litres/min

- Brass/Gunmetal Nozzles

Key Users

- Petrochemicals

- Fuel Storage Sites

- Oil & Gas

- Marine

- Major Industrials

- Aviation

- Chemical Facilities

- Nuclear

Delta Medium Expansion MX Bund Pourers are designed for both fire protection systems and vapour suppression in bunded or diked areas surrounding flammable liquid or toxic chemical storage tanks.

They are also ideally suited to other applications where large volumes of free flowing foam are required such as Process Areas, Warehouses and Cable Ductings etc. A fire in a bunded area can escalate extremely quickly and spread to adjacent storage vessels if not quickly controlled. A leak of un-ignited fuel from a faulty valve, cracked pipe or overfill can threaten the entire installation facility in a very short timeframe.

Delta’s MX Bund Pourers are designed to produce large volumes of medium expansion foam quickly and efficiently securing the bunded area from threat of ignition or toxic vapour release.

The MX Bund Pourer range consists of three lightweight, compact and robust options in nominal flows of 600, 1200 & 1800 litres per minute but can be flow-engineered to bespoke requirements to provide the correct application rate and optimum system cost.