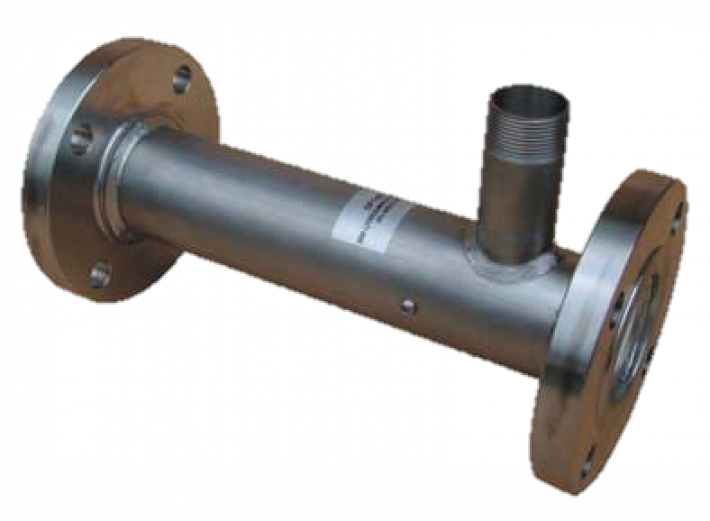

Fixed In-Line Inductors

Key Features

- Manufactured in the UK

- ISO9001 Quality Controlled

- Reliable, Economic Foam Proportioning

- Flow Engineered to suit Client

- 316 Stainless Steel or Painted Carbon Steel Options

- Flows from 50 LPM to 14,000 LPM

- Fixed or Variable Pick-Up

Key Users

- Petrochemicals

- Fuel Storage Sites

- Oil & Gas

- Marine

- Major Industrials

- Aviation

- Chemical Facilities

- Nuclear

Manufactured in the UK under an ISO 9001 Quality Management System the Delta Fire DFI Series of Fixed Inline Inductors are flow engineered to meet the specific requirements of the client. Designed to accurately proportion foam concentrate into a pressurised water supply providing an economic means of proportioning for systems requiring a fixed flow rate.

Each Inductor is factory calibrated to match the system flow pressure requirements. The proportioning rates can be accurately set at between 1% and 6%. Up to 65% of the inlet pressure is available to supply the downstream foam discharge devices and overcome pressure loss. Operating Pressure Range is between 3.5 bar and 16 bar.

Manufactured from high quality materials the DFI-Series of Fixed In-Line Inductors are incredibly durable and designed to provide many years trouble free use with minimal maintenance. Precision engineering and rigorous multi-stage quality controls ensures the very best of British manufacturing and excellent long-term value for money.

The Delta DFI-Series is widely used by Major Operators across multiple industry sectors around the world and has an enviable reputation for reliability and performance in the most demanding of environments.