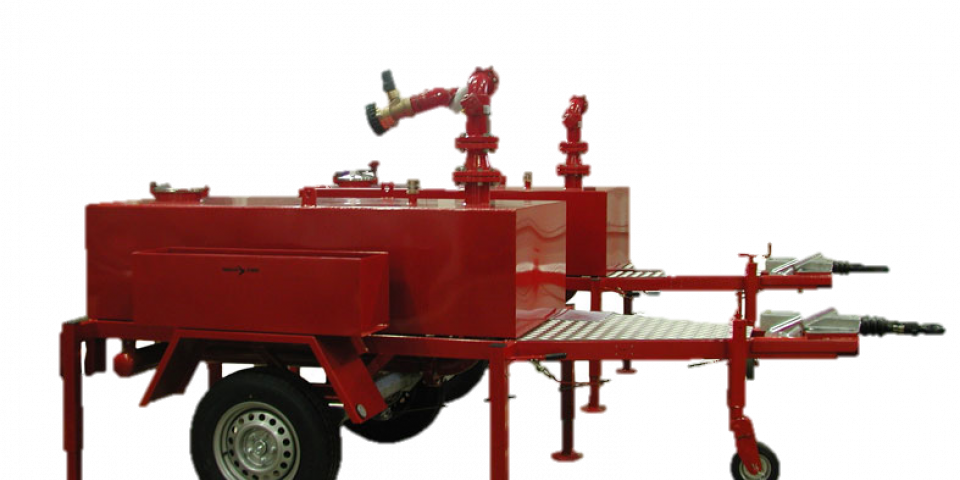

DF2000 Foam Trailer Monitor

Key Features

- Rapid Deployment

- Flows up to 1900 LPM

- High Capacity Foam Tank

- Long-Reach Capabilities

- Adjustable Horizontal & Vertical Elevation

- Twin Axle Carbon Steel Frame

- Vehicle Hitch System

Key Users

- Airport Fire Services

- Major Industrials

- Fuel Storage Sites

- Oil & Gas Installations

- Petrochemicals

- Waste Recycling

- Chemical Facilities

Designed for use in extreme risk situations the DF2000 Foam Trailer Monitor is constructed in corrosion resistant red powder coated carbon steel on a rugged twin axle chassis.

Supplied with stainless steel 2000 litre (530 USG) capacity foam tank the DF2000 provides rapid deployment and highly effective performance across a wide range of Industry sectors and applications. The single-axle rigid frame is fitted with mechanical stationary brakes and pneumatic tyres capable of movement over rough uneven ground. Four independently operated stabilisers ensure a solid operational platform. The DF2000 Foam Trailer Monitor offers easy vehicular connection via a 45mm tow-hitch for ease of movement around the risk site. The chassis is fitted with lights and rubber torsion bar suspensions.

Foam discharge is via the Delta UC2000 Ultra Compact Monitor fitted with a self-inducing Monitor Nozzle providing flows of 1900 LPM.