Fixed Foam Generators

Key Features

- Manufactured in the UK

- ISO9001 Quality Controlled

- Foam Maker & Injector Nozzle

- Available as Sets or Individually

- Ideal for Mudpits & Shale Shakers

- Fully Integrated Low Expansion Systems Available

- Bespoke Options Available

Key Users

- Petrochemicals

- Fuel Storage Sites

- Oil & Gas

- Marine

- Major Industrials

- Aviation

- Chemical Facilities

- Nuclear

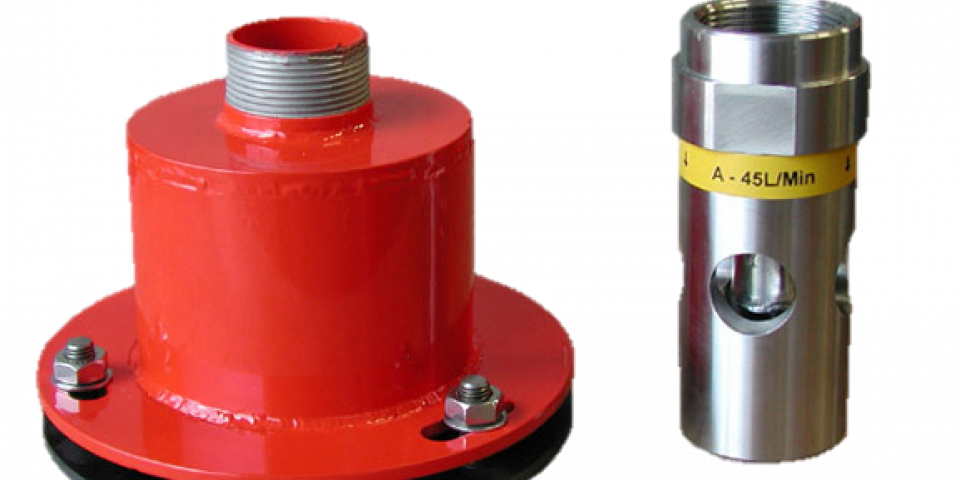

Delta Fixed Foam Generators comprise two principle components, the Foam Maker and the Foam Injector Nozzle (Top Hat).

Commonly used together for multiple applications including Mud Pit Systems, the Foam Maker is also available separately. This air aspirating foam discharge device can be used with all types of foam proportioning systems including bag tanks and balanced pressure proportioners. Applications include the protection of bund/dyke areas in low expansion foam systems, floating roof rimseal systems, foam pourers and spreaders, etc.

When pre-mixed foam solution is introduced into the inline Foam Maker, air is drawn into the device producing high quality, low expansion foam which is then injected into the risk area via the Foam Injector Nozzle (Top Hat).

Delta Fire provide a complete modular skid based low expansion foam fire extinguishing system which is easy to install into both new and existing mud pit tanks or shale shakers.

The Delta Fixed Foam generators can be supplied either as a set, as individual components or as part of a fully integrated system.